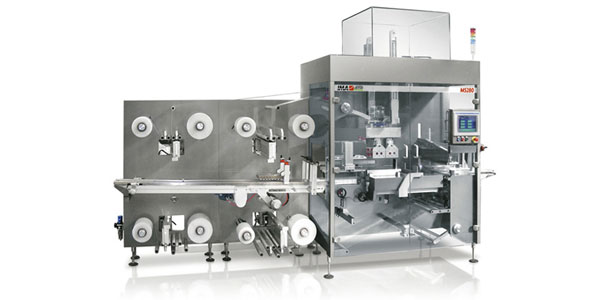

MS 250 A/AM/AP Stretch banding & shrink wrapping machine.

The MS250 bundling and wrapping machine has been specifically designed to meet the requirements of a market where demand is growing more and more for extremely compact, easy-to-operate, high production speed machines.

The machine can be equipped with a high speed stacking unit (MS250A) or with a carton tilting unit (MS250AM) capable of standing on edge as many as 400 cartons per minute.

Due to servo driven technological solutions this latest model can reach production speeds as high as 60 cycles per minute, thus making it an ideal partner to any high-speed packaging line for cartons.

The balcony-type construction of the MS250 allows for maximum accessibility to all its main parts in order to optimize maintenance and cleaning operations. Size change can be completed in approximately 5 minutes without the need to use tools and with all the adjustments being made with the assistance of digital indicators. The ergonomically mounted shafts are equipped with a quick expansion lock device to allow a quick change of the film reel. On request the MS250 can be fitted with a by pass mode which permits the product to flow through the machine.

Should shrink-wrapping be required, a shrink tunnel can be installed as an integral part of the machine.

The MS280 bundling and wrapping machine has been specifically designed to meet the requirements of high speed production lines.

Due to its fully servo driven technology this latest model can reach production speeds up to 100 bundles per minute. The machine is equipped with a pick and place unit capable of stacking cartons in several layers and/or collecting bottles in several rows (the shrink tunnel is required for bottles).

The balcony-type construction of the MS280 allows maximum accessibility to all its main parts in order to optimize maintenance and cleaning operations. All drives are located at the back of machine thereby separating them from the product flow area. The ergonomically mounted shafts, located outside the machine guards, are equipped with a quick expansion lock device enabling a quick change of the fi lm reels. A new electronic sealing system guarantees tight film wrap.

Size changeover can be completed in approximately 10 minutes without tools and with all the adjustments being made with the assistance of digital indicators.

Should shrink-wrapping be required, a shrink tunnel can be installed as an integral part of the machine.