Face mask production

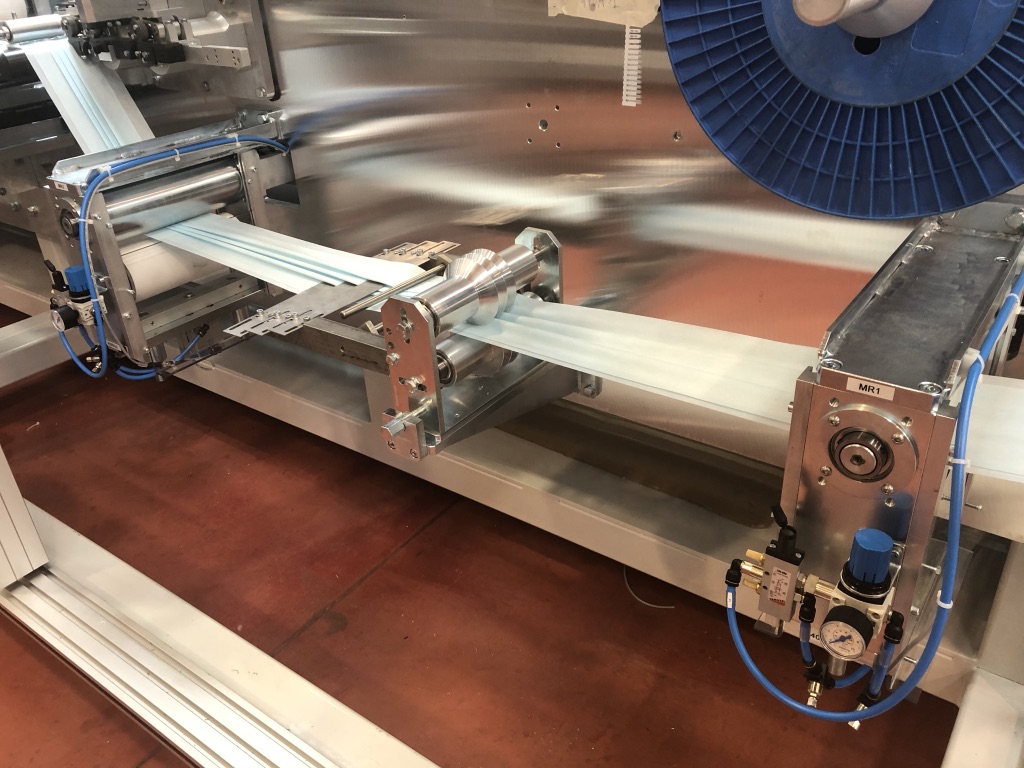

The IMA FACE 400 is a face mask converter based on a well-consolidated platform widely used to convert products made by lamination and welding of different fabric webs by hot melt or ultrasonic sealing. The unit is able to produce disposable surgical masks in 3 or 4 layers, with nose clips and elastic threads applied transversally to be worn “overhead” (behind the head) as standard. If desired, ear-loop style straps can be configured.

The FACE 400 also includes an automatic stacking device (1 – 40 masks) and allows a quick and electronic counting change over to be operated on its HMI avoiding any unnecessary machine stop.

This unit is designed and manufactured according to the latest sanitary design standards; this makes it extremely easy to sanitize and helps to keep the machine and products safe from undesired bacteria proliferation.

Speeds up to 400 pcs/min

The FACE 400 is capable to run from 200 up to 400 masks/min depending on raw materials and counting. It can be adjusted to produce different mask sizes by simply replacing the profile of the ultrasonic unit.

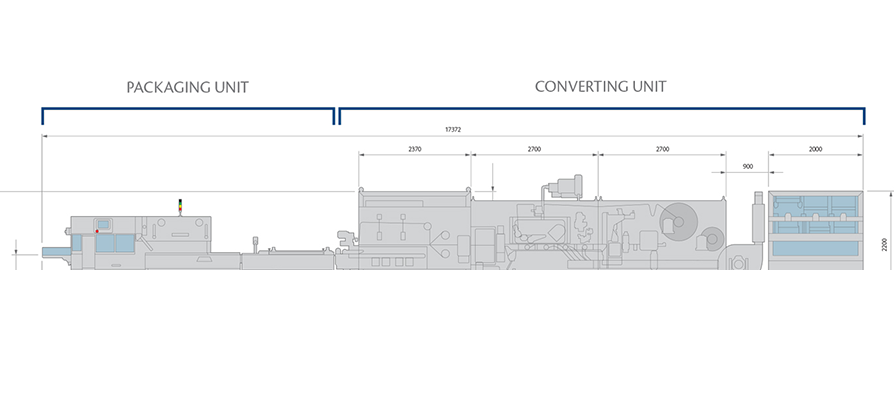

Packaging unit

The FACE 400’s optional packaging unit is a modular flow wrapper designed to handle surgical masks. Ideal for integration into complete lines thanks to an easy plug & play solution, it can also be provided with a manual feeding system for a stand alone application. This platform is available in different configurations aimed to handle any size of overhead mask as well as both short and long edge leading wrapping style.

Given this versatility, the machine allows to run stacks from 1 to 40+ pieces and also to handle multiple (parallel/adjacent) piles. Machine speed capability is up to 200 ppm with a single mask. Pillow packs with or without gusseting as well as euro hole feature are also available. Complete with automatic splicing device and a quality control system, it can also be equipped with an in line printing unit. Easy machine cleaning and accessibility are guaranteed according to the latest design standards.

Technical data

Face Mask Production (Coverting) unit

Machine speed: from 200 – 400 pcs/min

Mask dimensions: 200mm length x 100mm width (standard) – customised sizes available upon request

Mask materials: Standard 3 filtering layers: 2 layers of spun-bonded on upper and lower edges, 1 layer of melt blown in central area. Optional 4th filtering layer available, with no reduction in output. Additional material handling capabilities can be determined upon request.

Packaging (flow wrapping) unit

Machine speed: up to 200 cpm with single mask. Production output is dependent upon the product, film and machine specifications.

Stacks: 1 – 40 pieces

Maximum mask/stack size: 250mm length, 110mm width, 65mm stack height

Wrapping material: Suitable heat-sealable films such as plain or co-extruded polypropylene (PP), laminated films (OPPE+PE, polyethene films (PE), and cold-sealable films of suitable quality.