What are QIP Cams?

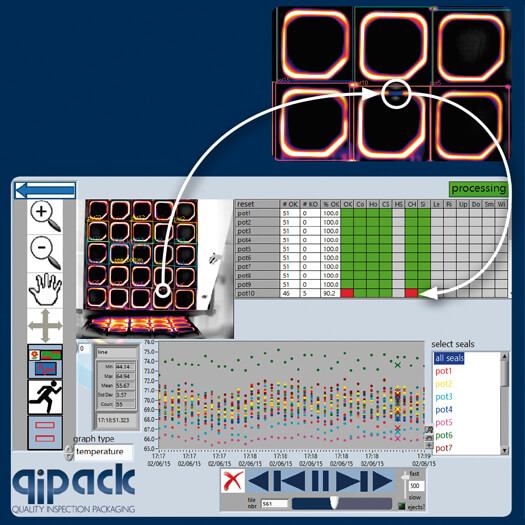

New seal check thermal inspection technology for seal quality is based on thermal, high-definition camera images. Following the production of the sealed item, an image is taken and analysed by special software. This highly-advanced and accurate thermal imaging results in remarkably clear information with respect to abnormalities in seal quality.

This analyses takes place during production, so that sealing defects are immediately detected, in-line and in real-time. The system works with all kind of laminate, printed and un-printed, with or without aluminium.

When a packed product fails the seal check test, it is pushed out by a rejecter unit for further investigation. Each individual package is therefore benchmarked on its impermeability, independent of the production rate.

- 100% of all packages inspected in-line

- Up to 150 strokes per minute

- 100% traceable and line performance detail

Packaging process improvement

Our solutions are capable of checking every single packaged item that is produced on almost any type of heat-sealing production lines. We visualise any type of defect, from product in seal, plies in laminate, pressure differences during sealing, to dirt on seal tooling. With this advanced seal check and leak detection, you not only detect leaks, but also prevent leaks in your future production processes.

The system does not interfere with the production process and does not affect production capacity. There is no limitation to the types of laminate or printing that are used.

What are the benefits?

Protect your reputation as a quality manager, brand reputation as a product manager, and profits as a business owner with thermal inspection seal checks.

- Stop product spilling

- Reduce quality claims

- Reduce wastage

- Reduce costs

- Guaranteed seal quality = guaranteed shelf life

- Less risk on recalls or complaints

- Less quality control needed and risk on rework

- Less product loss

- Satisfied customers!