Moulded wafer cones or cups are produced on semi- or fully automatic baking machines.

In case of semi-automatic production, the batter is poured manually by means of a dosing device into the cavities of the closed lower mould of the baking machine. The upper mould with the cone cores is raised and lowered several times with the cone cores dipping into the batter.

Then the moulds are closed, and the products are baked. After that the individual elements of the lower mould are separated from each other horizontally. The cones are released and fall into a collecting container below the baking mould.

In case of automatic production, the batter is poured after mixing by a depositor into the lower halves of open baking moulds which are mounted to a link chain. The upper moulds with the cone cores are lowered and moved up and down several times to let steam escape before final closing.

Then, the baking moulds run through the oven. After one turn, the upper moulds are raised, a stripping knive removes baking residues from the lower moulds. Next, the parted lower molds open, the cones or cups are pushed downward by an ejector and slide via a chute to a stacking device.

This device stacks the cones and moves them to the packaging table. In addition it is also possible to provide a sleeving machine that puts paper or aluminum sleeves between the single wafer cones during stacking.

Possible Products:

- Cones

- Cups

- Trays

- Fantasy shapes

Ice Cream Cone Baking Oven MTA

The MTA ovens are designed for the automatic production of molded ice cream cones, sugar cones (batter with a sugar content of up to 25%), wafer cups and wafer figures with a capacity of up to about 21,100 pieces/h.

MTA – Technical Data

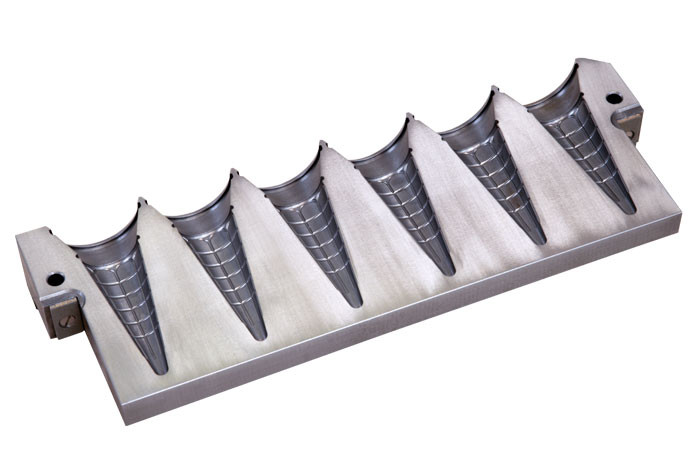

- 18 – 48 baking moulds of high-grade gray cast iron alloy with 4 – 11 cones/mold (depending on diameter)

- Baking moulds easily exchangeable (short change-over time), different products can be produced on the same machine

- Robust, modular design, easily extendable

- Gas-heated, all kinds of gas possible

- High-grade baking chamber insulation for efficient energy exploitation

MTA

- Ice Cream Cone Baking Oven E25 / E50 / E100

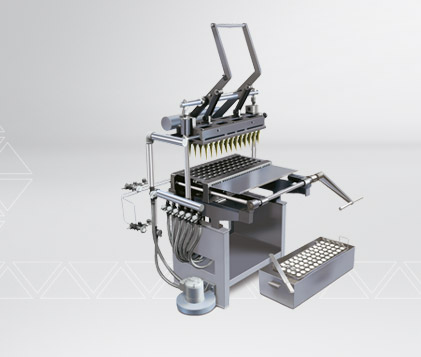

- The machines of the E-series are designed for the semi-automatic production of ice cream cones, cups and other deep hollow wafers. Depending

- On the product diameter, they have a capacity of up to 5,700 cones/h.

- E25 / E50 / E100 – Technical Data

- Very simple operation by hand lever

- Closing and pressing together of baking moulds by maintenance-free toggle joint system

- Exchangeable baking moulds

- Tilt-and-pour device for exact dosing

- Electrically or gas heated