Using standard components is the secret of success. Schubert’s highly flexible TLM packaging machines are designed for elegant, simple, manageable packaging of individual products – in other words anything capable of being picked up.

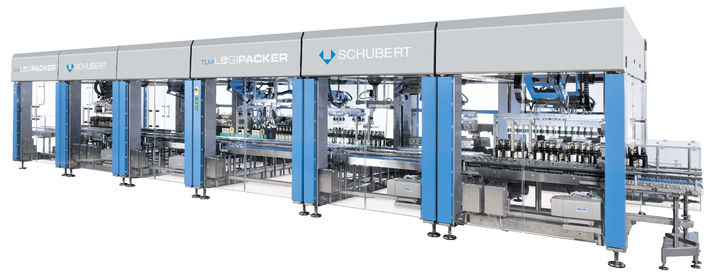

Bottle Cluster

260 bottles a minute, 8 different pack sizes from 4-bottle mutlipacks to 24-bottle trays and shipping cartons – quite a performance spectrum for a single machine. And what’s more – the multipacks not only have to be cluster packed but also placed into shipping cartons. The entire line is accommodated in an area of just 7 x 2,5 m – which means using one single TLM packaging machine. Despite the highly compact technology it contains, this machine still affords an exceptionally clear arrangement and optimum accessibility to everyone of its functions – as the industry has come to expect of a Schubert TLM packaging machine.

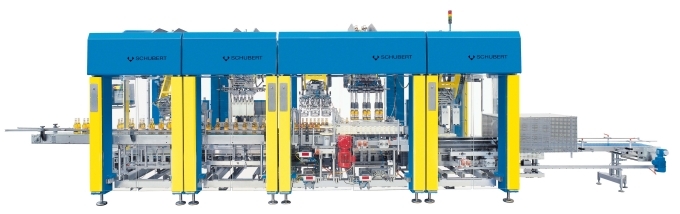

Mineral Water – top clip and sleeve

The bottles are fed towards the TLM-F44 robots along a continuously operating product feed belt. The TLM-F44 robots group the bottles on the grouping belt. During this process, the TLM-F44 vision system transmits wide-ranging data to the robots, such as the position of the bottles, the position of the label, or the presence of bottle caps. All bottles which are given a clean bill of health are picked off the infeed conveyor and positioned on the grouping belt. Where applicable, the robots ensure that labels are facing in the desired direction.

While the collated groups of bottles are transported towards the filling station in the final packaging plant, the first station is busy erecting the trays, sleeves, clips or boxes. In the filling station, the bottles are picked off the continuously operating grouping belt and placed in any one of the wide variety of different receptacles. In the closing station of the final packaging plant, the boxes are closed by a closing tool powered by a TLM-F2 robot unit. Simply changing the closing tool permits the use of every conceivable type of closing technique.