The HAAS fully automatic PKA ovens were especially developed for the production of pancakes.

PKA Technical Data

- 60 to 100 baking plates in the format 228 x 280 mm or 110 baking plates 228 x 480 mm (2 products/plate)

- Exchangeable baking plate insets for various product diameters

- Max. product diameter 190 mm, max. product thickness 10 mm

- Gas-heated

- Product take-off by rotating arms with vacuum suction disks or by vacuum drum

High-Capacity Pancake Baking Oven PAN

The fully automatic PAN ovens are used for the large-scale industrial production of pancakes.

PAN Technical Data

- Baking plate size 245 mm x 1830 mm

- Various product diameters possible by simple change of batter depositing system without baking plate exchange

- Max. product diameter 230 mm

- Oil spraying device for applying fat to the baking plates to achieve optimal baking results

- Gas-heated

Other Products

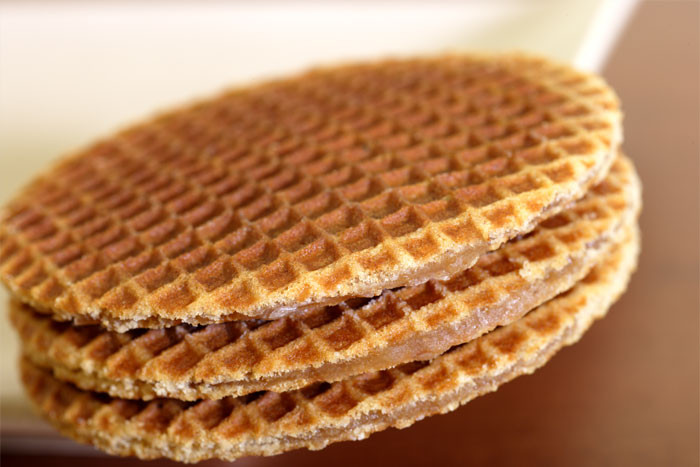

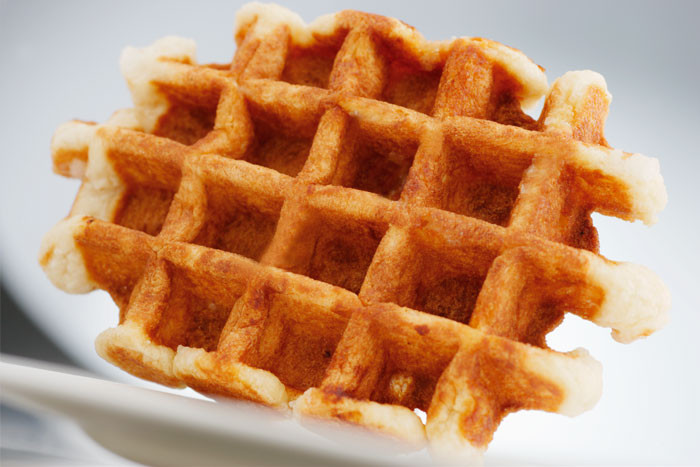

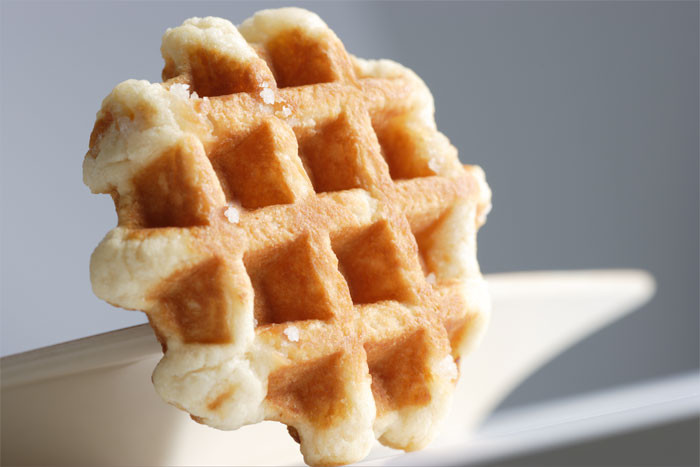

Special products such as Bricelets (round wafers), fan-shaped wafers, pressed wafers and Stroop waffles (round waffle sandwiches with caramel filling) are produced on special wafer baking machines.

At the oven head the batter is poured onto the lower plates of heated baking plate pairs. Then, the baking plates close and travel through the oven. After one turn, the baking plates open again at the oven head and are guided to a take-off device suited to the respective type of product.

For the production of Bricelets, a scraper removes the products from the baking plates and transfers them onto a conveyor.

Fan-shaped wafers, pressed wafers and Stroop waffles are released by take-off arms and passed on to the downstream equipment. A fan punch or a deep-drawing tool bring the baked wafer sheets into the respective shape.

The downstream equipment for Stroop waffles comprises a cutting machine, a combined decapping-depositing-capping unit and a cooler.

Possible products:

- Bricelets

- Fan-shaped wafers

- Pressed wafers

- Stroop waffles

- Crumpets