Bühler delivers total plant solutions for the finishing of confectionery and cookies to premium products.

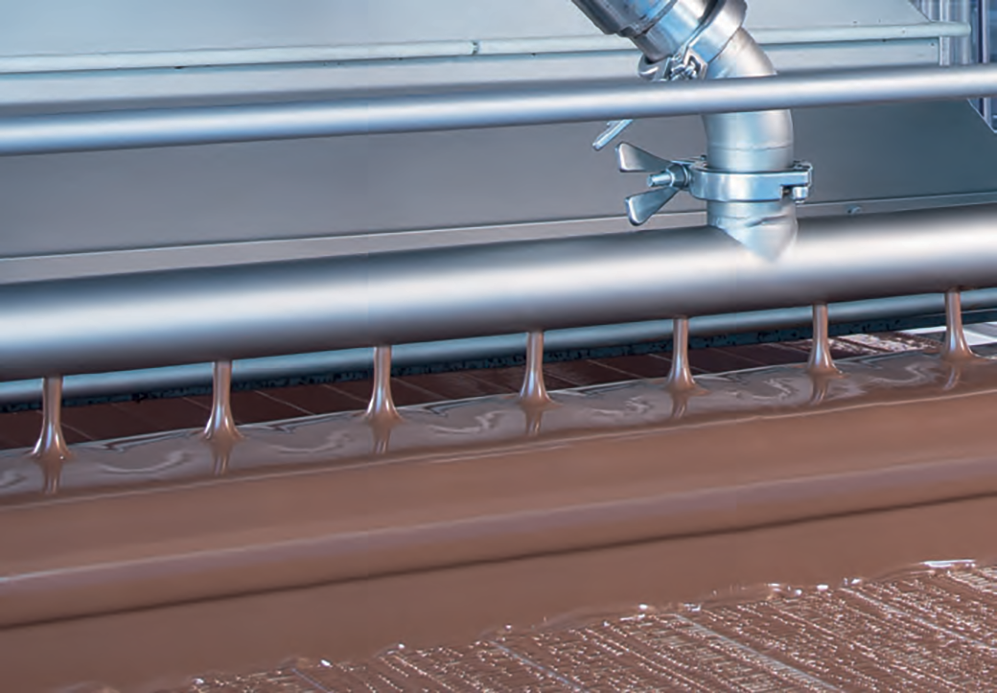

The secret to fine surfaces: For a perfect coating, the chocolate must first be exactly tempered. The perfection of Bühler tempering machines is demonstrated in the handling of masses with high viscosity while stringently complying with clearly defined crystallization points. They reproduce your top quality with consistency under changing climatic conditions or complicated factors.

Tempering

In the pre-crystallization of chocolate masses, two tempering machines function according to the principle of screw tempering which is distinguished by high precision and reliability in the processing. Both machines, BetaMat™ and TMK are designed so that even masses with chopped nuts or cereal can be processed.

Various size units handle production capacities ranging from 100 kg/h to 2,000 kg/h. The units are supplied with their own closed loop water circuits (one for each zone). The only utility requirement for cooling water to each of these loops is power. The new hygienic design (HD) gives improved access for maintenance purposes and also allows the unit to be easily disassembled for a basic wash down up to a complete allergen type cleaning.

Bühler tempering machines and conditioners:

• Standard compact tempering machines and compound conditioners.

• Throughputs from 100 kg/h to 2,000 kg/h.

• Perfect pre-crystallized enrobing masses.

• Suitable for highly viscous masses.

• Coating masses with inclusions possible.

• Integrated screw and crystallizers, screw warm- ers and cool water generator available. For the tempering machine, buffer tanks with chocolate pump are available.

• Quick and efficient mass exchange.

• Easy clean design results in quicker cleaning and change overs.

• Compact, space saving design.

The Bühler range includes tempering systems, enrobing systems, decorators and cooling tunnels which can be flexibly adapted to any product concept, mass recipe or production process. The experienced Bühler team effectively equips major companies in the confectionery and baked goods sectors with cooling and enrobing technology formerly known under the brand name Kreuter.

Bühler enrobing and cooling machines:

| Enrobing: | • ChoCoat™ • IceCoat™ for icecream • CaraCoat™ • Bottomer. |

| Tempering: | • TMK • BetaMat™ • Compact tempering machine • Compound Conditioner. |

| Cooling: | • HKK • HUKK • UKK • BKK. |

| Decorating: | • Integrated decorator • Servo decorator CW • Touch decorator • Decorating table. |