At Selpak, we have flexibility of choice for brand and machine types to cater to your specific packaging line needs. In terms of high-performance case packing, we tend to offer Schubert or IMA BFB solutions.

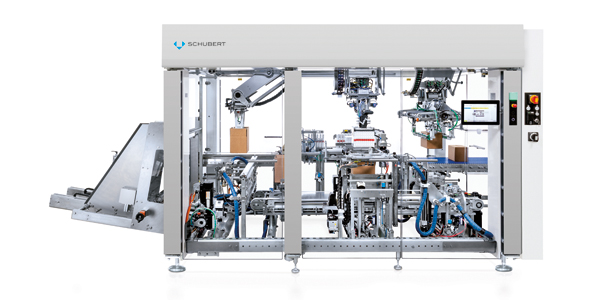

Schubert’s case packer functions similarly to their cartoning machine, where the packaging systems also handle the erecting, loading and closing of packaging materials. The difference is that case packer does not create elaborately designed packaging, but rather outer packaging or transport packaging for multipacks (cartons in case). These include wrap-around and RSC cartons as well as trays with and without lids. If cartons with shelf-ready function are used, they are also suitable for use on the sales shelf. The packaging materials are mostly made of corrugated cardboard, but our case packer can also process reusable boxes made of plastic. A pre-grouping system, which is perfectly adapted to the products and packaging, and the F2 robots ensure space-saving loading.

With their lightline Cartonpacker, less really is more. It is close to a ‘third’ less expensive, can be delivered a ‘third’ more quickly and requires a ‘third’ less space. As a preconfigured case packer, it offers Schubert’s proven robot-assisted technology at a significantly more affordable price and a very short delivery time of three to four months. In a single compact machine frame, Schubert has condensed its decades of experience in handling case packing and developed an automation solution that delivers maximum availability and outstanding packaging quality. For manufacturers of consumer goods, the lightline Cartonpacker is an ideal way to position themselves on the market quickly and sustainably with future-proof packaging processes.

IMA BFB’s Side loading case packer is suitable for the packaging of individual or bundled cartons into pre-glued RS cases.

IMA BFB’s machine footprint is extremely compact and it is the ideal solution in case of space restrictions at the end of the line.

Main features

– Cantilever design on both sides for great accessibility and easy cleaning

– Quick tool-free changeover

– PVC or hot melt case closure

– Case positive erection and loading

Optional groups

– Case overturning device

– Product tracking system

– Entirely driven by servomotor

– Labeller and marker integration

– Camera detection system

The CP38 is a high-speed side loading case-packing machine specifically designed to handle loose or bundled cartons. This machine has been developed in response to new market requirements such as the cantilever design of its structure which ensures complete accessibility and easy cleaning.

In addition, great importance has been given to the ergonomic position of all its components. The CP38 is, indeed, the only case packer on the market where all the parts of the machine can be reached from the operator’s side without having to walk to the opposite side to reach the carton stacking unit area.

In order to be as “operator friendly” as possible the case erecting mechanism of this machine has been completely redesigned to ensure extremely low positioning of the horizontal case magazine. This guarantees long autonomy.

As dictated by the most modern requirements of technology, the CP38 is entirely driven by servo-motors which means dedicated strokes and motions for each specific application. Servo technology and innovative solutions allow the machine to achieve a very high speed (up to 30 cases/min) with smooth product handling and compact footprint.

The case is erected and held in position on two sides during the loading operation. This system is very effective allowing handling of lower quality corrugated cardboard. Once loaded, the case is discharged by sets of upper and lower belts with lugs, thereby maintaining constant and perfect control of the product. Cases can be closed with adhesive tape or with hot-melt glue. The tool-free size change-over is simple and can be carried out in a matter of minutes with the assistance of a large and comprehensible operator interface. The machine also features a standard PLC unit.

The CP38 is fully guarded by full size transparent panels interlocked with safety switches in order to meet CE requirements.

Optional groups

– Case labelling and label verification

– Case rejection at discharge

– Case overturning at discharge