HAAS DECOQUEEN devices are used for decorating dough ropes with jam, jelly or other doughs, which have a consistency similar to that of a deposited biscuit dough.

DECOQUEEN – Technical Data

- Extrusion pressure provided by two fluted roller pairs

- Decoration substance pressed through nozzles onto the dough ropes

- Lateral fine adjustment by hand wheel, amount controlled by changing speed

- Hopper and rollers of stainless steel

- Fluted rollers of hard chrome plated special steel

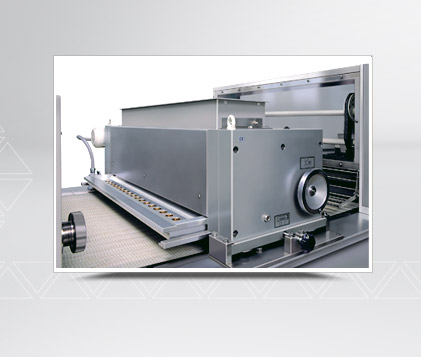

Oil Spraying Machine SOLE

The Oil Spraying Machine SOLE is designed for spraying products with oil, fat or liquid flavors.

Oil Spraying Machine SOLE – Technical Data

- Products on a stainless steel wire mesh band run through the spraying chamber

- Available working widths: 1000, 1200, 1400, 1500 and 1600 mm

- The oil is applied by means of 2 rows of rotating disks each above and underneath the band

- Oil container capacity: approx. 75 l, controlled by a PLC, fitted with a heating system

- Regulation of spraying quantity by pump speed and by disk rotation speed

Decorating Device DECOQUEEN

The DECOQUEEN devices are used for decorating dough ropes with jam, jelly or other doughs, which have a consistency similar to that of a deposited biscuit dough.

DECOQUEEN – Technical Data

- Extrusion pressure provided by two fluted roller pairs

- Decoration substance pressed through nozzles onto the dough ropes

- Lateral fine adjustment by hand wheel, amount controlled by changing speed

- Hopper and rollers of stainless steel

- Fluted rollers of hard chrome plated special steel

Mini Depositor Type 3950

The Mini Depositor Type 3950 is designed for decorating cookies, Danish pastry, biscuits, pizza and for injecting liquid substances, marmalade, cream, icing, ketchup, as well as fruit and candy substances into different types of cakes.

Coating Device STRV

The coating device serves to coat the entire surface or the contours of dough blanks with coating masses such as egg wash or glaze.

STRV – Technical Data

- Maintenance-free all-steel construction of stainless steel

- Coating mass taken out of tank by dipping roller, transfer to intermediate roller, application by brush roller (for coating entire surface) or steel roller (for coating contours)

- Brush roller with natural or nylon bristles

- Quantity of coating mass regulated by roller speed

- Rollers driven by frequency-controlled three-phase motor

Oil Spraying Machine SOLE

The Oil Spraying Machine SOLE is designed for spraying products with oil, fat or liquid flavors.

Oil Spraying Machine SOLE – Technical Data

- Products on a stainless steel wire mesh band run through the spraying chamber

- Available working widths: 1000, 1200, 1400, 1500 and 1600 mm

- The oil is applied by means of 2 rows of rotating disks each above and underneath the band

- Oil container capacity: approx. 75 l, controlled by a PLC, fitted with a heating system

- Regulation of spraying quantity by pump speed and by disk rotation speed