Principle

- High shearing effects at optimum energy intake thanks to special designed conching tools

- Wide range of temperature profiles for flavor development

- Developing structural changes during conching

Aims

- Moisture reduction and stripping – off unwanted volatiles

- De-agglomeration and release of immobilized fat

- Redistribution of aroma components

- Development of flavor

Applications

- Control shaft speed according to drive current

- Air forced ventilation concept for efficient volatile and moisture reduction

- Control on shaft direction to maximize impact on de-agglomeration

FRISSE™-ELK S single-shaft conche.

for efficient conching

- Short conching cycles and lower fat consumption in comparison to other conche.

- Software system which allows automatic control of all the process steps.

- Minimized maintenance, resulting in high machine uptime.

- High energy efficiency thanks to direct drive.

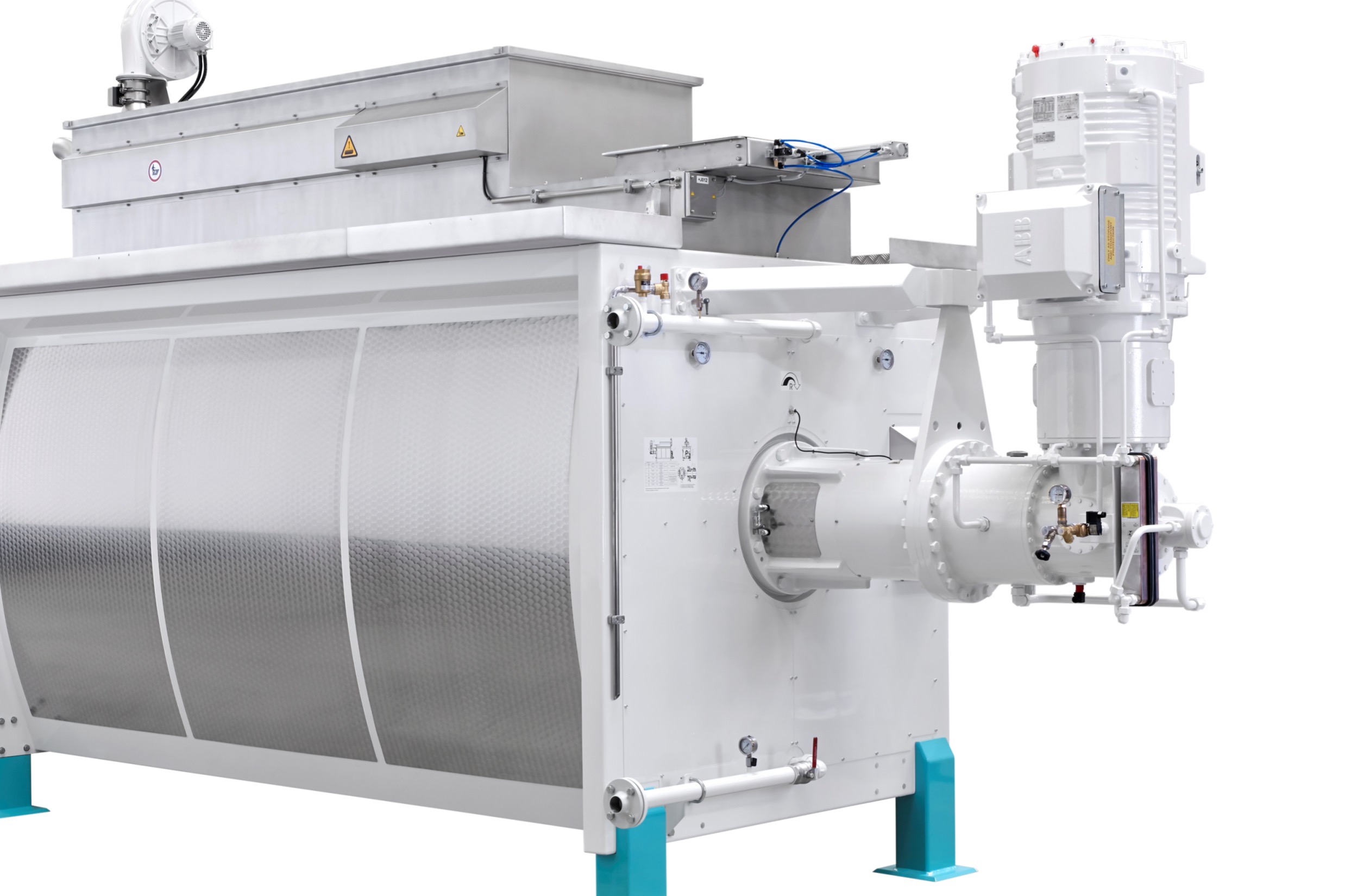

FRISSE™-DÜC S triple-shaft conche.

for superb conching

- Shortest conching cycles at lowest possible fat utilization thanks to overlapping shearing.

- Latest sanitation and safety standards.

- Reduced machine footprint thanks to new drive configuration.

- Improved vessel design for less product residues.