IMA SAFE’s reputation is based on having the widest range of solutions for blister and tray packing on the market and for the highest level of service in terms of sales, technical support and assistance.

IMA blister packaging machines have been an undisputed world leader since the early ‘70s when the company introduced for the very first time the monobloc integrated blister packaging machine/cartoner with an extremely compact footprint.

The main concepts characterising and inspiring the design and production of IMA solutions for blister packaging are: - Very high OEE – Overall Equipment Effectiveness - Ease of use (size changeover, repeatability, cleanliness, batch change, maintenance) - Safety: maximum safety for the product and the operator.

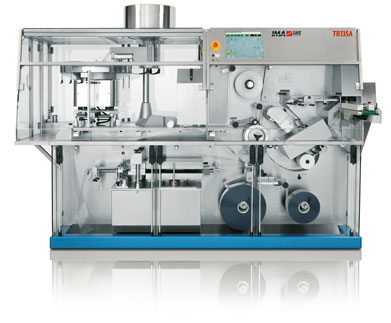

TR135

TR135 is an extremely versatile, medium production speed blister packaging machine that was designed for production cycles that require frequent size changeovers.

Giant

Giant1 is a perfect alternative for just-in-time production of small and medium batches with only 7 metres footprint with a jumbo forming reel holder. Designed for both multinational pharmaceutical companies as well as contract packers, it fully responds to the most complex production requirements worldwide.

The machine concept has been based on the IMA philosophy of flexibility in operation and changeover combined with easy cleaning and less material/product waste.

The machine has a careful functional design in the main working groups that are completely servomotor assisted. High efficiency in production is assured thanks to an integrated connection and reduced changeover times, limited number of size parts, which have been specifically designed to weigh less than 20 lbs (9 Kg).

On the Giant1 IMA has developed a patented cutting solution to solve the problems of “product recall”, which guarantees that rejected faulty blisters cannot be matched in further packaging processes due to their different shape.

C80/A81

C80-A81 is the perfectly integrated 2-row blister line suitable for just-in-time production, which requires rapid changeover from one product to another and simple adjustments. Along with its compact and modular design, the technical features make the C80-A81 a masterpiece in blister packaging.

The C80-A81 has almost no limits in packaging dimensions and is extremely flexible when switching from 1- to 2-row production and vice versa. It works with any packaging material, handles any blister, carton and leaflet dimension, all carton closures and cartoning materials. High efficiency is guaranteed thanks to several applied solutions such as positive blister transport system.

The A81 integrated cartoner was designed for the highest flexibility in carton handling and for maximum efficiency in blister introduction into the carton. The line boasts a fast and easy changeover with a reduced number of parts to be changed and extreme accessibility for maintenance operations, controls, and installation of additional devices.