RoastMaster™ Series

RoastMaster™ 20

Great flavour creation with the flexible and user-friendly coffee roaster. Ideal for start-up businesses and small-scale industrial operations require to produce top-quality coffee.

RoastMaster™ 60

Leading the way in excellence and efficiency for coffee flavour creation. Offers a maximum of process flexibility with a single batch capacity of 60 kg and an hourly throughput up to 240 kg/h.

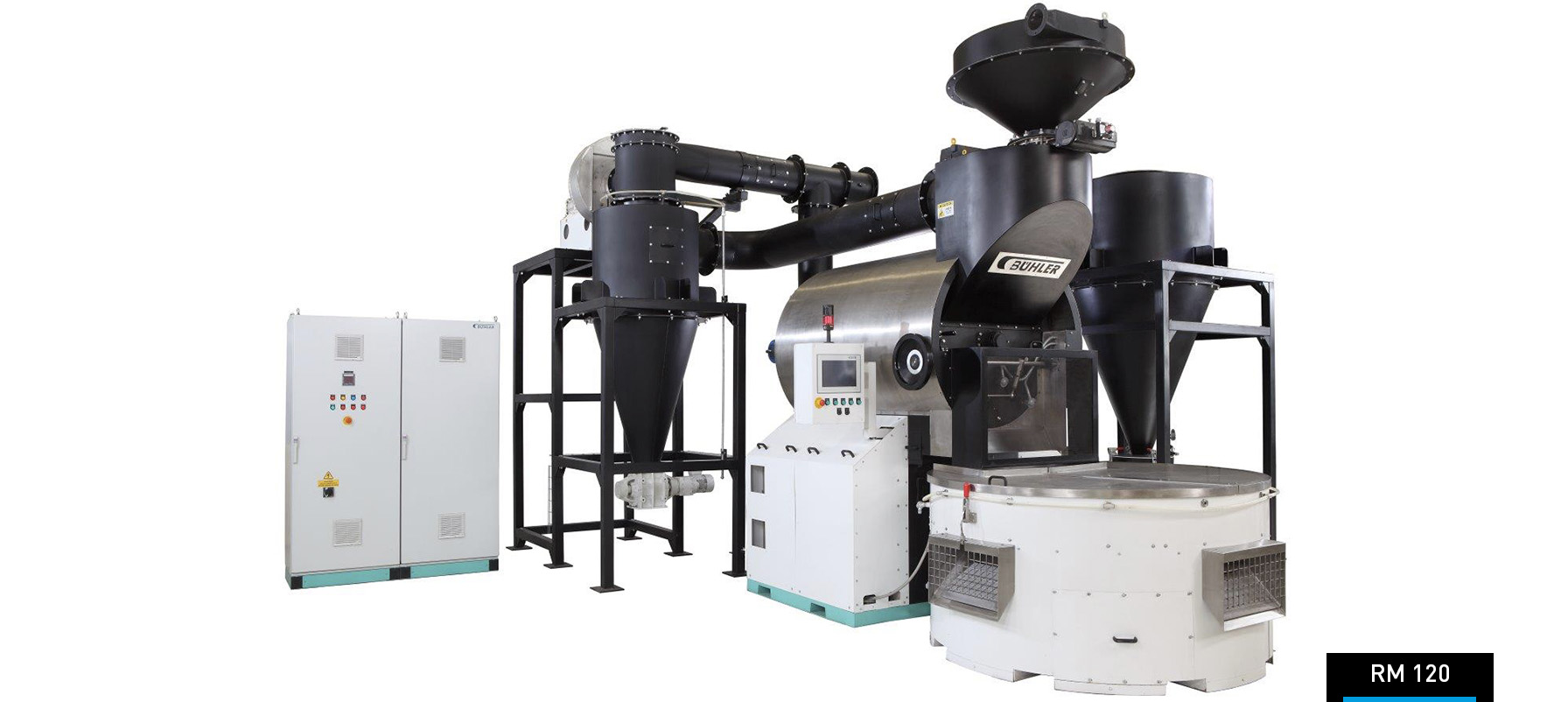

RoastMaster™ 120

Create your own roast flavor signature. Whether traditional or innovative new roasting profiles, the RoastMaster™120 offers a maximum of process flexibility

(other Bühler machinery include, Coffee: conveyors, grinders, after burners.)

InfinityRoast™

A new dimension in coffee flavor creation. InfinityRoast™ coffee roaster. Widest process flexibility for creating the bean’s flavor signature.

The InfinityRoast™ will inspire your product innovations and assist you in creating traditional and non-conventional roasting profiles for customised flavour characteristics and physical bean properties. With the InfinityRoast™ you are in control.

The InfinityRoast™ next-generation coffee roaster is leading the way into the future of roasting. Designed for high-performance operations, it sets superior standards in flavour generation, safety, reliability, energy-efficiency and environmental impact. The InfinityRoast™ series combines a unique type of roasting chamber which is suitable for operation with low or

high air-to-bean ratios with the benefits of a highly efficient, gentle round-bed cooler. This unparalleled combination is the key to producing consistent, superior coffee products.

- Flexibility for traditional and non-conventional roasting profiles.

- High-performance roasting control.

- Operational efficiency.

Bühler Barth

Bühler Barth GmbH delivers machines, plants and turnkey factories for the confectionery industry, more specifically for the treatment and processing of cocoa, nuts, grain and malt.

State-of-the-art technology for all processes.

Your coffee creations deserve the best.

Coffee is our passion and inspiration. Bühler is your partner for innovative complete coffee processing solutions. We empower you to transform beans into ultimate coffee sensations for your consumers.

Bühler is the undisputed global technology leader in food production. For more than 40 years, Bühler has been building equipment for coffee processing and complete coffee systems worldwide. Whether for small, medium or large-scale coffee operations – Bühler offers customised solutions that meet your individual needs. Our proven expertise spans the entire range of coffee processing, from green coffee intake, cleaning, sorting, handling, roasting, grinding to degassing.

Our roasting technology sets new standards for flavour generation. It allows you to create your own unique traditional and non-traditional roasting profiles for optimal flavour characteristics and physical bean properties. Sophisticated process control systems ensure the most consistent results and safe operations. Our solutions always give high priority to energy efficiency and environmental protection.

Roasting & Debacterising: High-grade raw materials such as cocoa beans will only develop their unique flavour and the desired colour if a suitable roasting process is applied.

Cocoa Beans – from process to flavour.

The increasing demands being placed on the special flavour characteristics of high-grade cocoa beans require flexible processes. Specific applications need to be selected for cocoa varieties of very diverse origins such as Ecuador, Venezuela, Côte d’Ivoire, Ghana, Brazil, and Sulawesi.

The different roaster types of Bühler Barth allow product-specific settings to be selected which determine the degree of roast. The selection of similar or entirely different temperature profiles with a highly flexible retention time in the roasters allow almost unlimited possibilities of flavour development. The pyrazine content of the cocoa beans is used as an indicator for the roasted flavour as well as for the reproducibility of the roasting process.

Nut roasting and pasteurising.

The NR roasting system is characterised by the fact it develops a good product flavour and ensures an optimal shelf life and uniform degree of roast. Especially the high oxidation resistance achieved has a highly beneficial effect on the shelf life of roasted hazelnuts, peanuts, almonds, and cashew nuts. In addition, a novel pasteurising process for almonds efficiently reduces the germ count while leaving the visual appearance of the treated almonds unchanged and minimising the water absorption capacity.

Modularity meeting your needs.

Modular components allow an almost unlimited flexibility for every application. Customised system modules are available to accommodate any required throughput capacity. The configuration of the modules produces a small machine footprint and allows the available building space to be efficiently utilised.