Yamato is the leading manufacturer in the domain of multihead weighing technology. Be it for weighing, mixing or counting your product, Yamato provides innovative weighing, packaging and product inspection solutions.

Dataweigh Omega

Dataweigh Omega series provides customers with significant benefits, such as improvement in “productivity”, “operation”, “maintenance”, “food safety” and “environmental responsibility”.

High-speed and high-accuracy weighing

- The improved weighing system is faster than 200wpm, and increases production yield. It realises a reduction of the production line and reduces the consumption.

- Auto-tuning of feedback amplitudes together with Yamato’s Automatic Feeding Control (AFC) realizes optimum product flow.

User-friendly operation

- The large 12.1-inch LCD touch screen and 3D animated images make operation easy for anyone.

- With Auto-tuning, feeder amplitudes and motor pattern of bucket gating are automatically set. It removes the stress associated with complicated operation.

Ease of maintenance

- The load cell withstands up to 150kg, so that extreme caution is not necessary for maintenance and cleaning.

- Various information for quick recovery with alarm display and replacement time display for consumable parts.

Food safety

- The IP67-compliant body can be washed perfectly to eliminate accumulated product particles and prevent the growth of bacteria.

- YDB buckets have no space for dust and bacteria propagation and no aging degradation on the bonding plane.

- *YDB bucket is applicable to specific models.

- The polygon-shaped bucket is easy to clean as it is light and rigid and corners are an obtuse angle.

Power consumption is reduced by 60%

- Dataweigh Omega series contributes to cost reduction and to saving the environment.

- Clear Product Window for perfect sealing contributes to the reduction of packaging waste during production.

Dataweigh Sigma F1-Frontier

Advantages of Dataweigh ΣF1 series

1. Increase productivity of Packaging System

・ Maximize efficiency of plant

・ Minimize production loss

2. Expand the market

・ Increasing packaging machinery efficiency across a wider range of pack styles

・ Expand Bagmakers

3. Environmental Benefit

・ Reduction in packaging waste

・ Use of lighter gauge materials

Bottom Based Handling of ΣF1 series

・ Maximize sealing time

・ Minimize sealing failures

・ Improve seal integrity

・ Improve efficiency

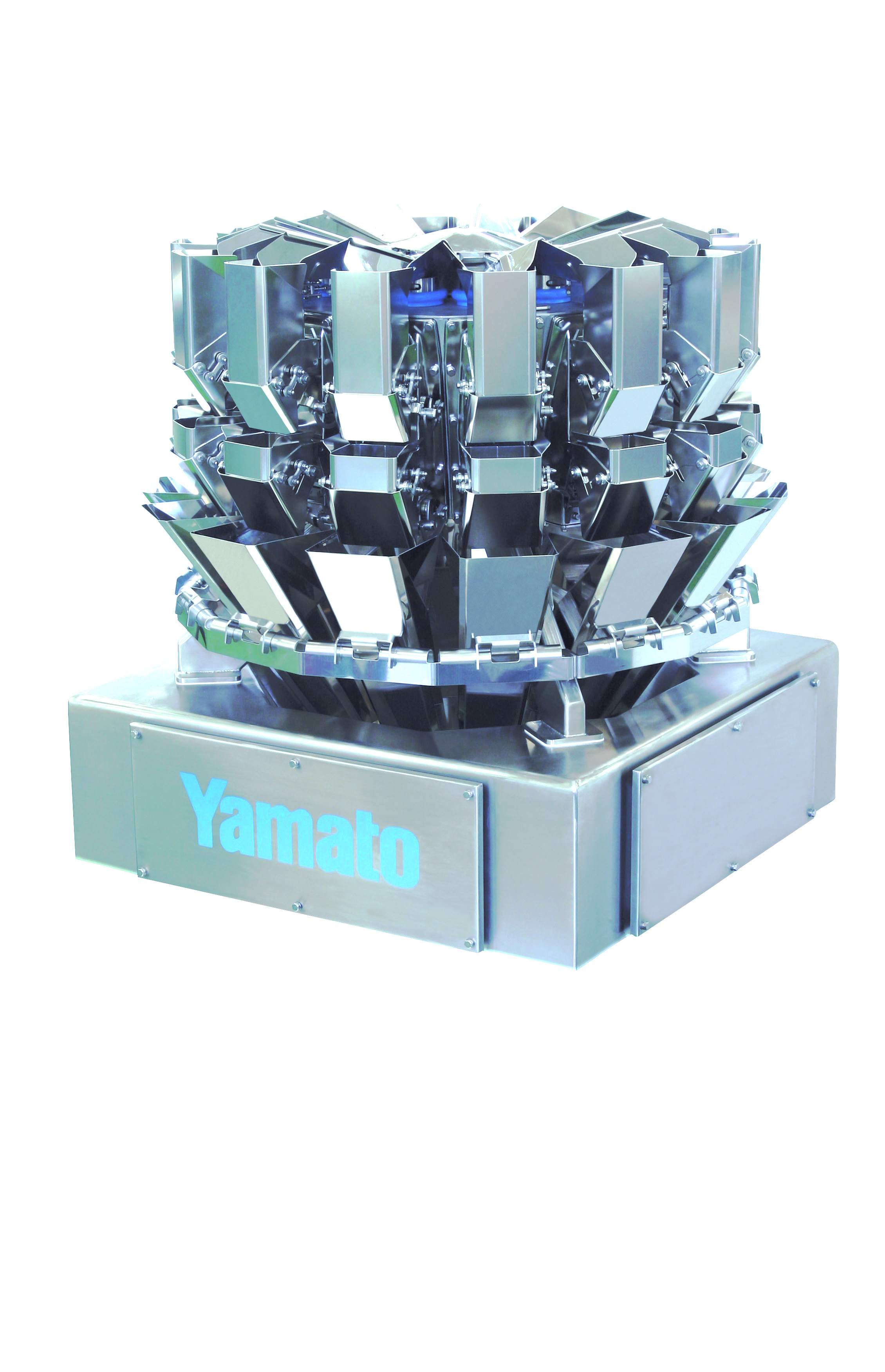

Dataweigh Alpha plus

It’s combination of user and supplier friendliness enables improved cost-effective performance in packaging free flowing products. The ADW-510ACC is characterized by it’s easy operation and simple maintenance. It’s compact design offers the most advanced technology.

Compact Design

The compact body size, not only enhances its installation capabilities but also helps reduce cost for peripheral equipment such as support stands and product feeder.

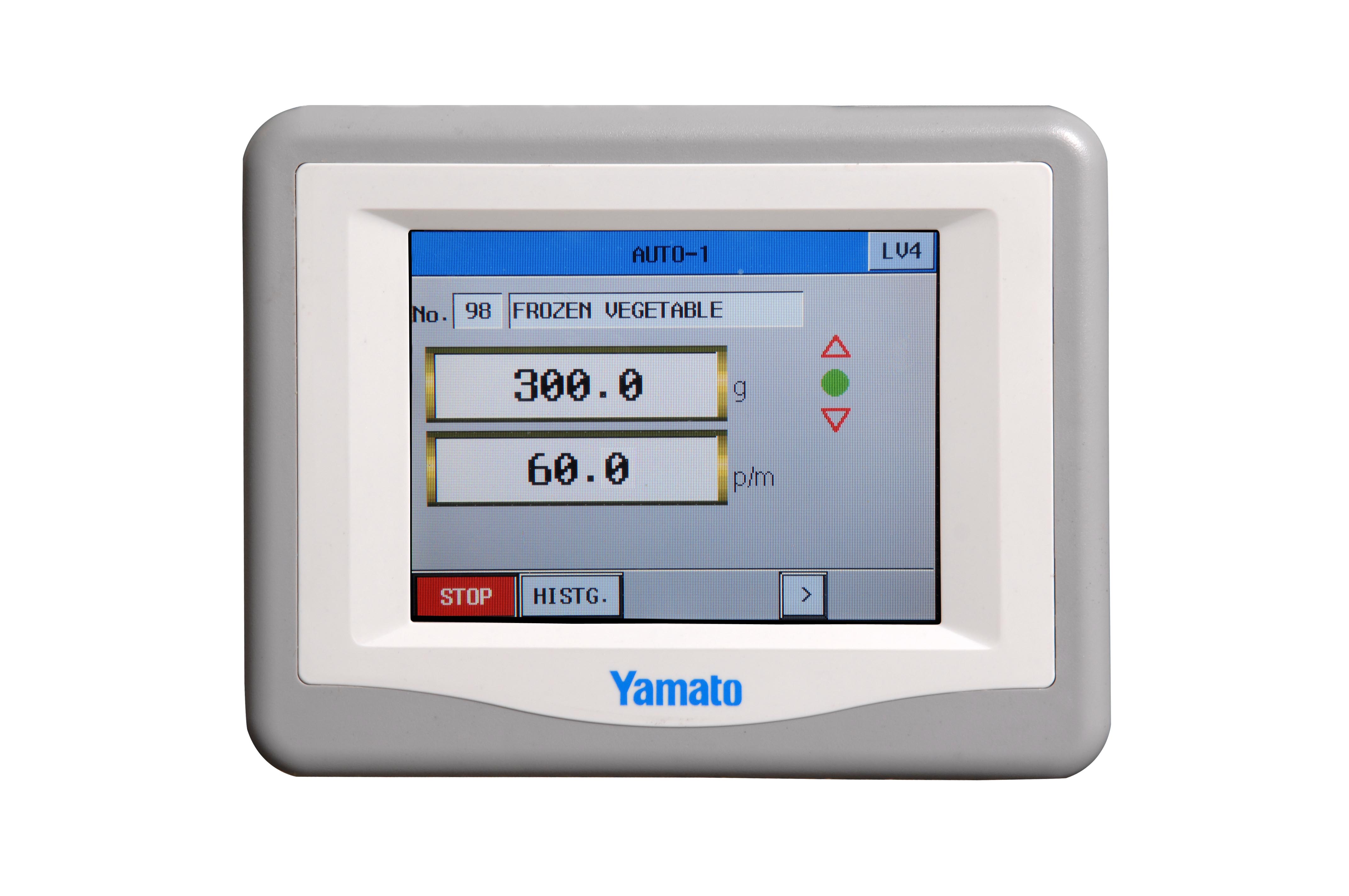

Colour Controller

A user-friendly designed Compact Color Controller provides simple opera-tion with integrated functions. It is capable of memorizing 100 product programs.

Radius Corner & Springless Bucket Design

The springless bucket design with large radius corners makes it easy and quick to clean. Radius corner buckets are easy to clean reducing downtime.

Weigh Sensor

The load cell level detector under the top cone controls the product flow from the scale feeder ensuring proper feed conditions to maximize efficiency and accuracy.

The color touch screen displays the amount of product on the top cone.