Continuous Aseptic Spray-freeze-drying

Lynfinity is just a drop away

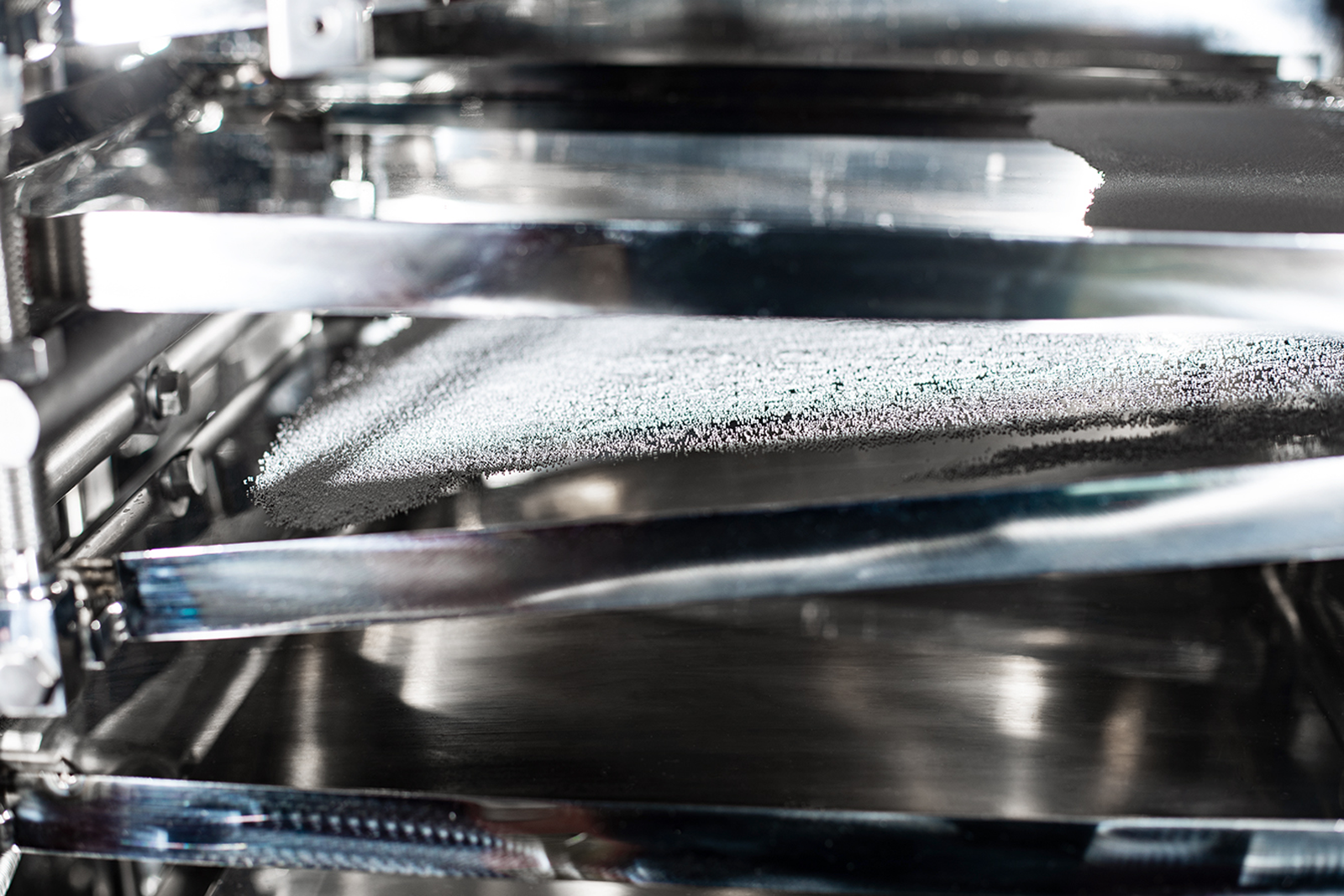

An innovative solution coming soon to industrial production is a new spray-freeze-drying process, which controls a spray of liquid product into a cryogenically cooled freezing chamber. The resultant frozen particles fo the liquid product are freeze-dried in the drying module and the frozen spheres are then packaged into a variety of containers, such as vials, syringes, and inhalation systems.

A laboratory version of the Lynfinity continuous spray-freeze-drying system is available, with an industrial production level version being developed for future release soon.

IMA LIFE division, in the field of liquid powder and aseptic and non-aseptic processing, can today offer a wide range of machinery, particularly designed to meet the most stringent pharmaceutical requirements, from very advanced machinery and applications through to traditional filling and closing machines.

Combining the role of machinery supplier with the added ability to be a solution provider for its customers, IMA LIFE can satisfy new requirements of aseptic and pharmaceutical markets, offering a product which represents not only consolidated technology, gained during many years of experience but which also derives from a continuous partnership with pharmaceutical multinationals worldwide.

IMA LIFE aseptic and pharmaceutical products are intended for applications requiring equipment of high scientific and technological content, where the industry must comply with very strict standards. In this market, the company can either manage large-scale projects designing and manufacturing customized solutions to meet special end-user requirements, ensuring that end-user time to market deadlines are met.

Almost 150 machines a year are produced in the filling field, most of which are integrated into complete processing lines, due to an intimate knowledge of machine integration and line functioning logic, which is guaranteed by dedicated facilities and staff for equipment assembly integration.

Two different production sites ensure the wide range of machinery, one located in Calenzano near Florence and one in Ozzano near Bologna, each one specialized in a specific part of the process.

Machinery:

- Bottle blowing

- Vial washing

- Sterilization Tunnels

- Liquid Filling

- Syringe filling and closing

- Powder filling

- Ampoule filling

- Alu Capping

- Isolation technology

- Freeze Dryers