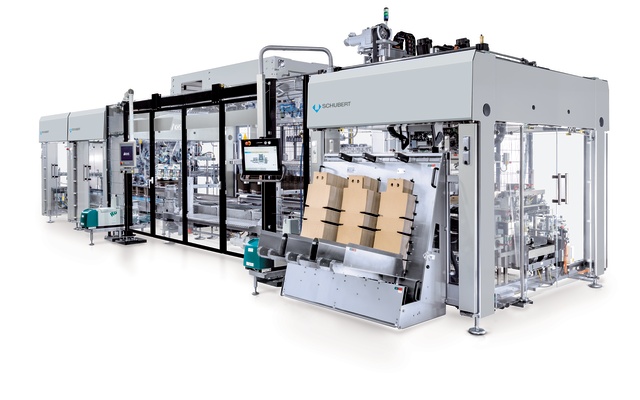

Retailers are demanding more and more shelf ready packaging. Taking the form of RSC / HSC cases with perforations, Wrap around case with perforations, or Tray and Lid (Hood) packaging. The Schubert TLM packaging machine with its inherent flexibility can handle all forms of shelf ready on the same machine with just a simple tool free changeover.

The TLM Packaging machine series is based on the top-loading concept. The packaging process starts with the erection of boxes. Flat box blanks are fed from the transfer units, erected by the TLM-F2 robot units fitted with erecting tools and transported by Transmodule to the filling and closing stations. The same TLM-F2 also erects pre glued RSC case’s.

The products are conveyed to the packaging machine either in mass flow or single file. Filling of boxes generally takes place using TLM-F2 robots fitted with relevant filling tools. Where extensive regrouping functions are required, two TLM-F2 robots are used in conjunction with a grouping table.

A TLM-F2 fitted with the relevant tool is used to close the box. This process can involve gluing a separate lid part over the box base using a wrap-around method. The use of robot tools enables the high-speed changeover from one closing method to another. Their enormous flexibility allows TLM packaging machines to be used for both end loading and wrap around processes.

Bags:

Approximately 100 bags per minute are fed in on a continuously running belt. The TLM picker station then groups them on a grouping belt to form package layers. After that, they are fed to a TLM-F2 robot. The TLM box erector erects the shipping carton. It can be either a pre-glued folding case or a flat box blank.

Trays:

Up to 200 sealed trays per minute are fed into the TLM packaging machine. The products are grouped and loaded via TLM-F4 robots controlled by the integrated visions system. The wrap round carton is erected then closed via a TLM-F2 after filling is completed.